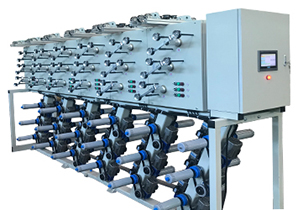

Motorized Creel

Model YDA10

Tension control range 10~1000g

Tension control accuracy ≤±5 %

Work speed 0.5-150m/min

Tension control range 10~1000g

Tension control accuracy ≤±5 %

Work speed 0.5-150m/min

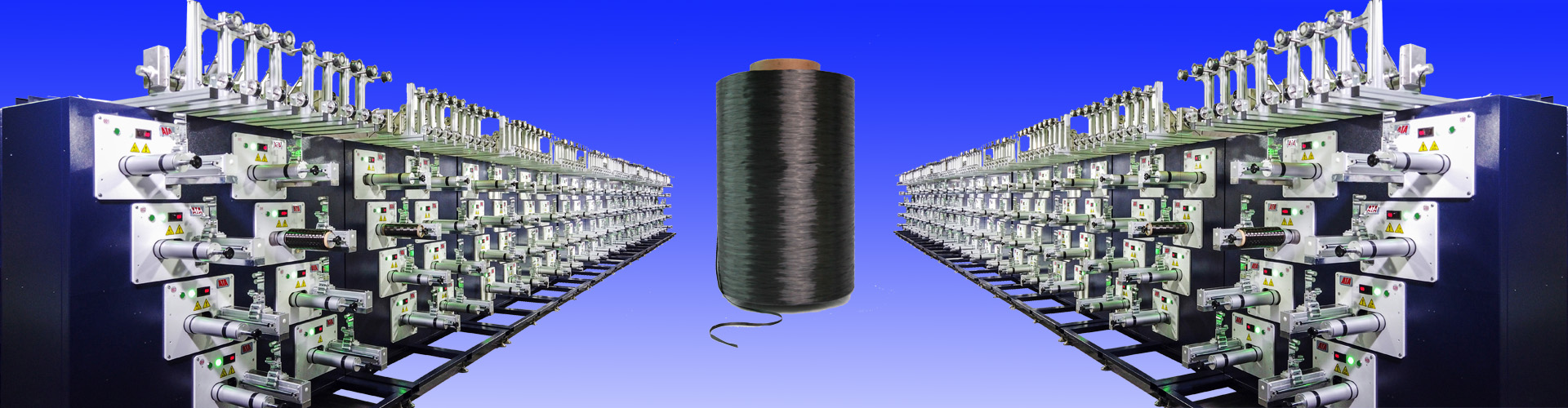

Applications

It is suitable for high-precision controlled tension unwinding of aramid yarn, glass fiber, carbon fiber and other spindles. It is also suitable for large and small tension and low-speed and high-speed unwinding requirements.

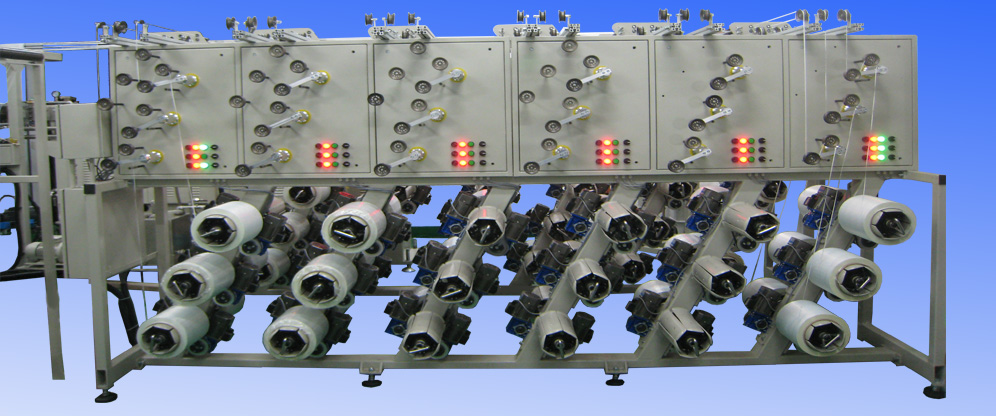

Operation process

The yarn fray is unwinded by the godet wheel, rotated and cut the yarn to release the yarn, and then enters the tension control system, and then passes through the aluminum alloy godet roller for the guide wire collection, and then enters the subsequent equipment. Unwinding is driven by a motor, controlled by a vector controller, and a sensor senses the tension to form a closed-loop control system.

Operation process

The yarn fray is unwinded by the godet wheel, rotated and cut the yarn to release the yarn, and then enters the tension control system, and then passes through the aluminum alloy godet roller for the guide wire collection, and then enters the subsequent equipment. Unwinding is driven by a motor, controlled by a vector controller, and a sensor senses the tension to form a closed-loop control system.

Structure and composition

Structure and composition

Dexterous structure design

- It is composed of four parts: frame body, spindle, tension control, and wire guide wire;

- Spindles are arranged in a single-sided structure, combined and arranged according to actual requirements

Dexterous structure design

- The simple plastic mold spindle structure facilitates the loading and unloading of the spindles, which can greatly save the time for spindle replacement.

- Compact structure, space saving, flexible placement according to actual needs.

- Various layout designs can be carried out according to the use characteristics and customer needs.

- The motor drives the spindle to rotate and unwind.

- The sensor senses the change of tension and feeds it back to the inverter.

- The inverter receives the tension change signal and controls the unwinding speed of the motor.

- High unwinding precision, stable tension, control precision ≤±3%

- Reasonable unwinding distance, minimize unwinding angle and save space

- Each thread has its own path, so it won’t hurt the thread without rubbing it.

- All guide wire elements are rotating parts, and the surface is smooth and wear-resistant without damaging the wire

- Closed loop control, high precision of tension control

- Large and small tension, high and low speed unwinding can be designed to meet the needs, and the scope of application is wide

- The tension is evenly adjustable, will not rub or hurt the thread

- Smart structure design, easy to use

Technical Specification

| Tension control accuracy | ≤±5% |

| Tension control range | 10-1000g |

| Tension control method | Motor driven unwinding |

| Speed range | 0.5-150m/min |

| Bobbin ID | 76、94mm |

| Bobbin length | 290、350mm |

| Bobbin material | Paper bobbin;plastic bobbin |

| Max. Spindle diameter | φ300mm、 |

| Traverse Length | 250mm |

| Max. Spindle weight | 10kg |

| Yarn collection surface width | According to customer requirements |

| Yarn collection surface height | According to customer requirements |

| Equipment color | According to customer requirements |

产品图集

HOME

HOME