Winding Speed 150-600m/min

Max Bobbin Diameter 300mm

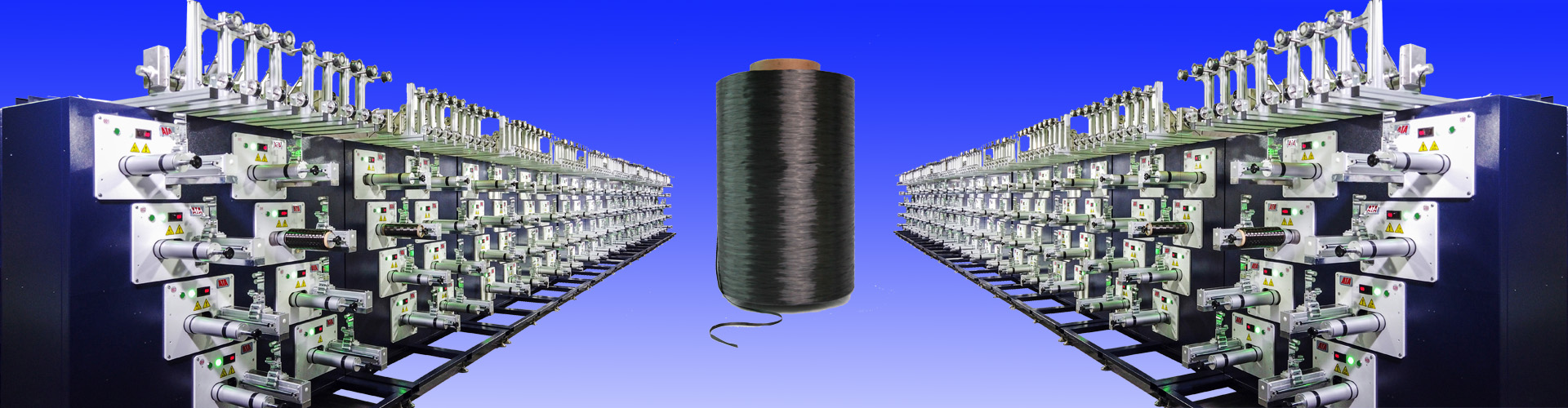

The winder is designed for speciality fiber, its special function of auto change-over can ensure to save cost, reduce labor intensity and improve production efficiency for the users.

Big spindle with good quality, max winding diameter of 300mm.

All winding parameters can be input and stored electronically, switching variety of fibers quickly and effectively.

Variable electronic winding ratio, to ensure the tension inside and outside big spindle consistent.

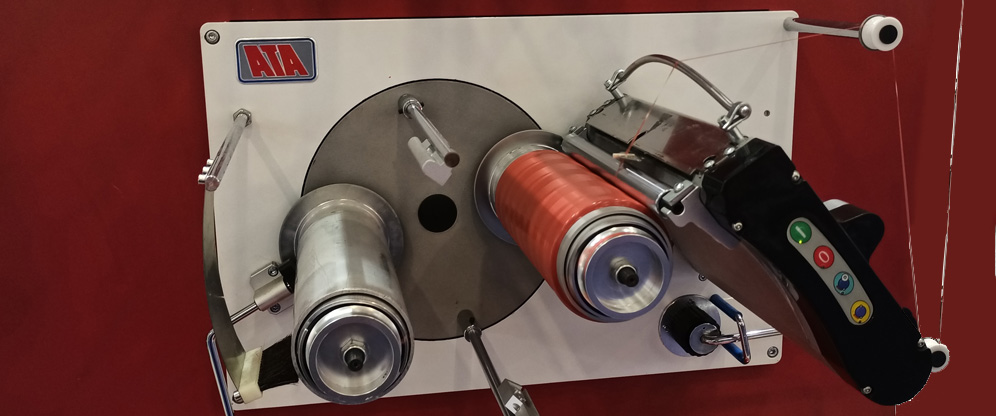

Dual motors, independent drive, reduce the link of connection and transmission, decrease the maintenance cost.

Control mode of change-over: set by yarn length and winding diameter of spindle.

Special structural design, successful rate of change-over up to above 99%.

Mechanical characteristics and optional items:

Reduce the pressure of yarn press roller(The pressure will reduce with the winding diameter enlarges)

Reduce the tension of yarn(Pneumatic&controllable tension bar)

Special coating surface of yarn guide roller(Optional: yarn guide roller with orange skin surface treatment)

Meter counter and capacity inquiry(Optional: increase capacity inquiry and immediate speed display)

| Winding Ratio | Electronic |

| Titer | 180-3000dtex |

| Winding Speed | 150-600m/min |

| Max Bobbin Diameter | 300mm |

| Tube ID | 50/76/90mm |

| Tube Length | 220\270\300mm |

| Traverse Length | 200\250\270mm |

| Yarn Tension | 100-1200cN |

| Frame Structure | 3 tiers, single row |

HOME

HOME