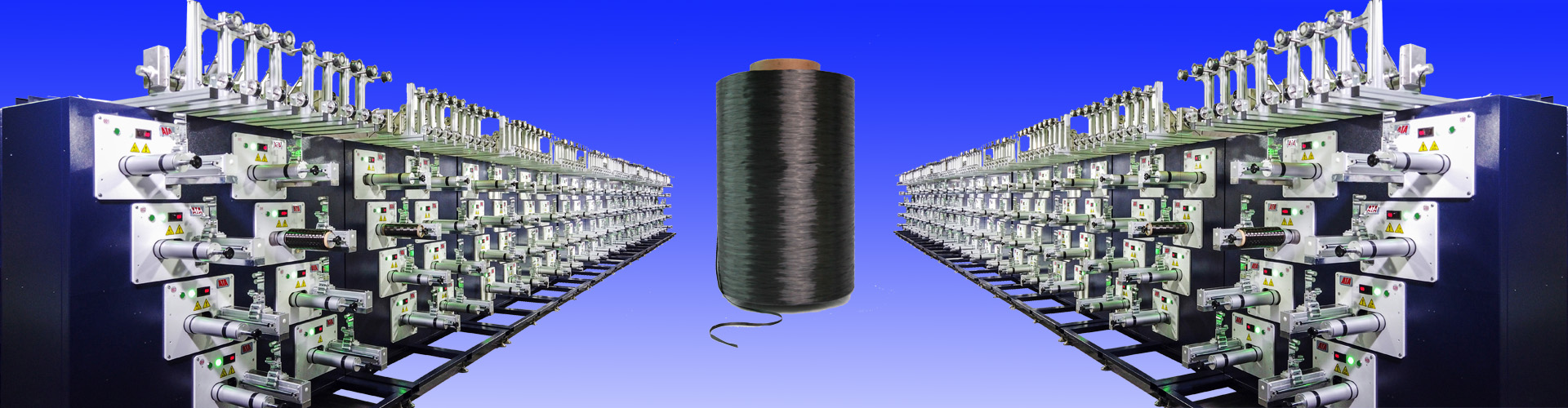

AW11F Winder

Titer 100-1500 dtex

Winding Speed 800 m/min

Maximum Bobbin Diameter 250mm

Winding Speed 800 m/min

Maximum Bobbin Diameter 250mm

Product application

The winder suitable for: Aramid fiber

The winder is specially designed for the winding of aramid fiber, which fully considers the characteristics of aramid fiber. The unique yarn feeding method and automatic changeover function ensure that the spindle is perfectly formed without damaging the fiber, to ensure the consistency of quality of the spindle and save labor and labor intensity.

The winder is specially designed for the winding of aramid fiber, which fully considers the characteristics of aramid fiber. The unique yarn feeding method and automatic changeover function ensure that the spindle is perfectly formed without damaging the fiber, to ensure the consistency of quality of the spindle and save labor and labor intensity.

Technical characteristics

- Fully auto change-over, suitable for high-speedy production line, max speed of 800m/min, change-over based on fixed length mode and fixed winding diameter mode, without yarn wastes in the process of change-over.

- Electronic winding ratio: precise electronic winding ratio, it can achieve precise winding through randomly changing winding parameters and patterns according to the specification of fiber.

- Variable winding ratio: it can be set randomly which is benefit to the winding of big spindle with the perfect shape and without the fallen yarn.

- Electronic tension control: it can be adjusted online through the uniform setting on man-machine interface. The tension is balanced and consistent with high precision.

- Yarn feeding structure: special design of two-roller down yarn entrance with less touch point which can reduce the friction for fiber to an extreme and avoid damaging the quality of fiber.

- Contact pressure control: special design of contact pressure method, can be set uniformly through the man-machine interface. The contact pressure will reduce gradually with the winding diameter enlarges.

- Traverse control: adopting servo drive, high precision of yarn guide and perfect shape.

- Yarn guide roller: all yarn guide roller adopt ceramic surface treatment which have no damage for yarn with high durability.

- Processing parameter storage: all processing parameter can be stored in PLC and used directly after confirmation. It can store max 10 kinds of processing parameters.

Technical specification

| Titer range | 50-3000dtex |

| Winding Ratio | Electronic |

| Winding Speed | 350-800m/min |

| Maximum Bobbin Diameter | 250mm |

| Yarn Tension | 50-1100g |

| Tube ID﹡ | 94mm |

| Tube OD | 106 mm |

| Tube Length﹡ | 290mm |

| Traverse Length﹡ | 250mm |

| Frame Structure | 3 tiers, single row |

产品图集

HOME

HOME