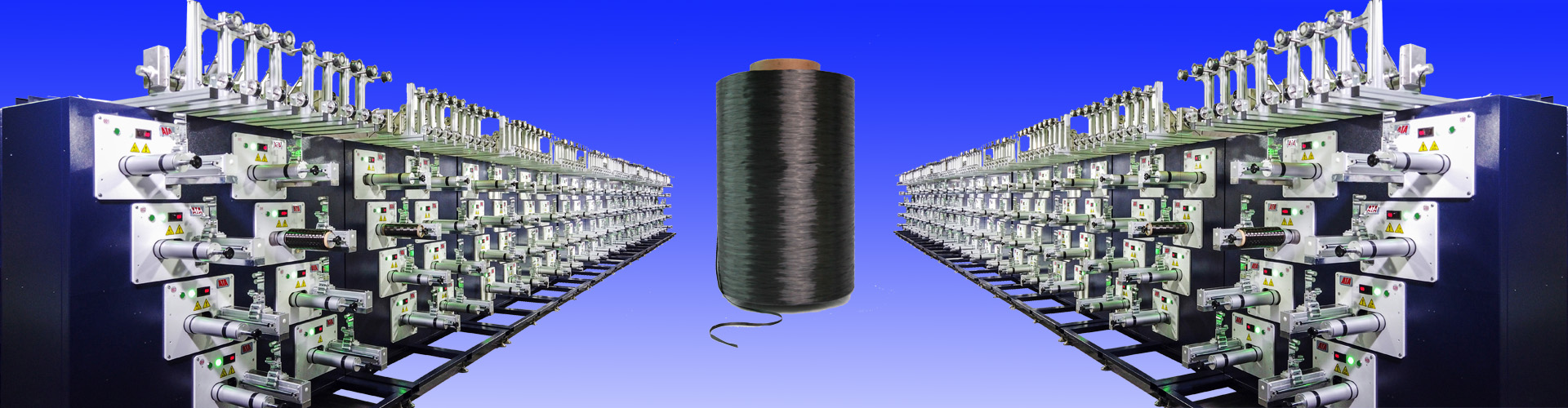

AW11 Winder

Titer 100-1500dtex

Max.Winding Speed 800 m/min

Max. Bobbin Diameter 250mm

Product Application

AW11 of winder suitable for: Aramid fiber, PBO fiber, UHMWPE fiber, PIfiber, high performance ceramic fiber.

The winder is designed for the high-speedy rewinding of high performance fiber, fully auto rewinding according to the pre-set fixed length mode and fixed diameter mode, to ensure the consistency of quality of the spindle and save labor and labor intensity.

The winder is designed for the high-speedy rewinding of high performance fiber, fully auto rewinding according to the pre-set fixed length mode and fixed diameter mode, to ensure the consistency of quality of the spindle and save labor and labor intensity.

Technical characteristics

- Fully auto change-over, suitable for high-speedy production line, max speed of 800m/min, change-over based on fixed length mode and fixed winding diameter mode, without yarn wastes in the process of change-over.

- Electronic winding ratio: precise electronic winding ratio, it can achieve precise winding through randomly changing winding parameters and patterns according to the specification of fiber.

- Variable winding ratio: it can be set randomly which is benefit to the winding of big spindle with the perfect shape and without the fallen yarn.

- Electronic tension control: it can be adjusted online through the uniform setting on man-machine interface. The tension is balanced and consistent with high precision.

- arn feeding structure: special design of two-roller down yarn entrance with less touch point which can reduce the friction for fiber to an extreme and avoid damaging the quality of fiber.

- Contact pressure control: special design of contact pressure method, can be set uniformly through the man-machine interface. The contact pressure will reduce gradually with the winding diameter enlarges.

- Traverse control: adopting servo drive, high precision of yarn guide and perfect shape.

- Yarn guide roller: all yarn guide roller adopt ceramic surface treatment which have no damage for yarn with high durability.

- Processing parameter storage: all processing parameter can be stored in PLC and used directly after confirmation. It can store max 10 kinds of processing parameters.

Technical Specification

| Titer | 50-3000dtex |

| Winding Ratio | Electronic |

| Winding Speed | 350-800m/min |

| Maximum Bobbin Diameter | 250mm |

| Yarn Tension | 50-1100g |

| Tube ID﹡ | 94mm |

| Tube OD | 106 mm |

| Tube Length﹡ | 290mm |

| Traverse Length﹡ | 250mm |

| Frame Structure | 3 tiers, single row |

产品图集

HOME

HOME